The Industrial Data Platform (IDP) from CANCOM Austria is a central data platform specifically designed to increase efficiency and transparency in industrial production processes. It offers a holistic solution for challenges such as isolated data silos, heterogeneous IT and OT structures and a lack of connectivity in manufacturing.

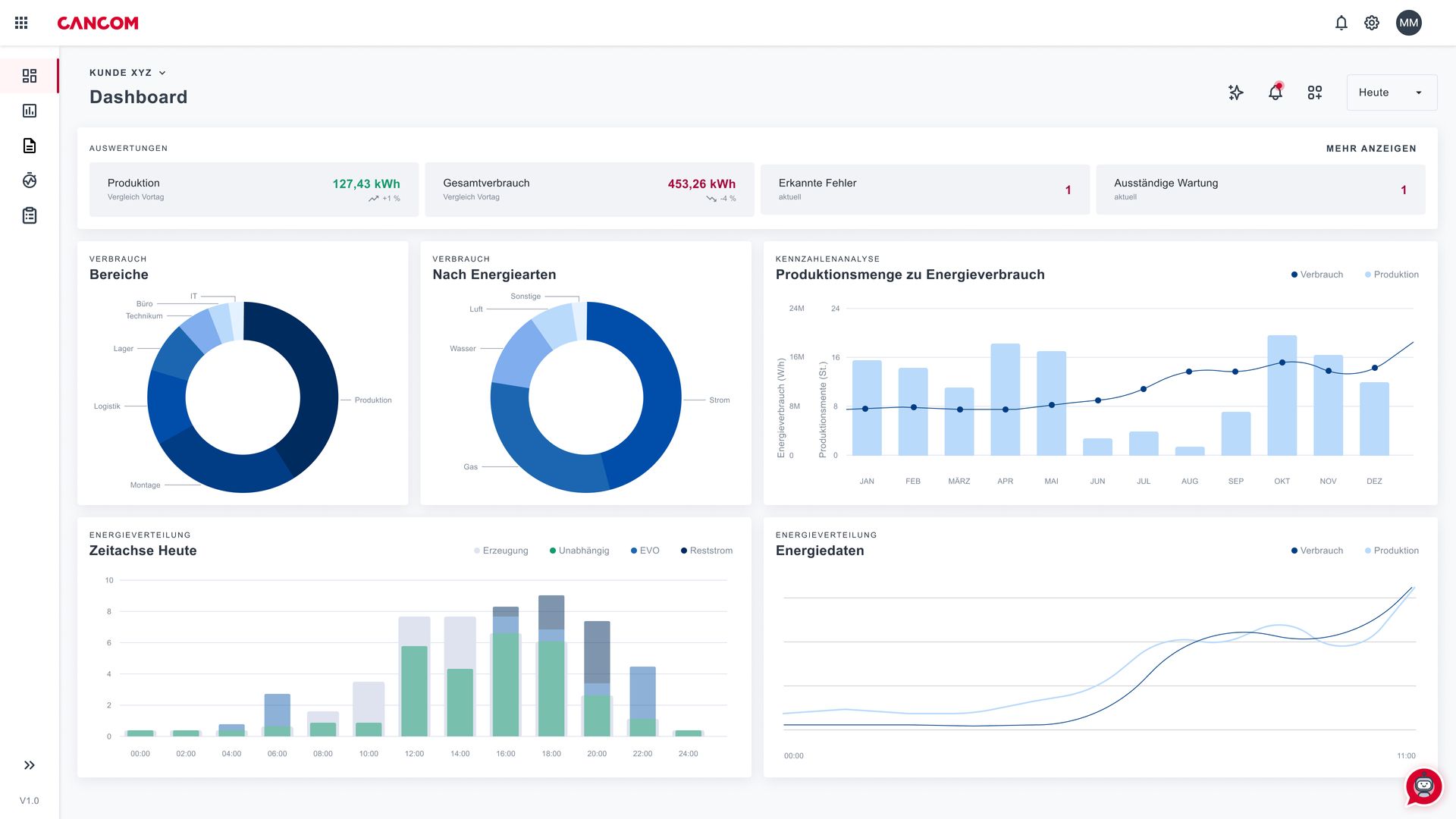

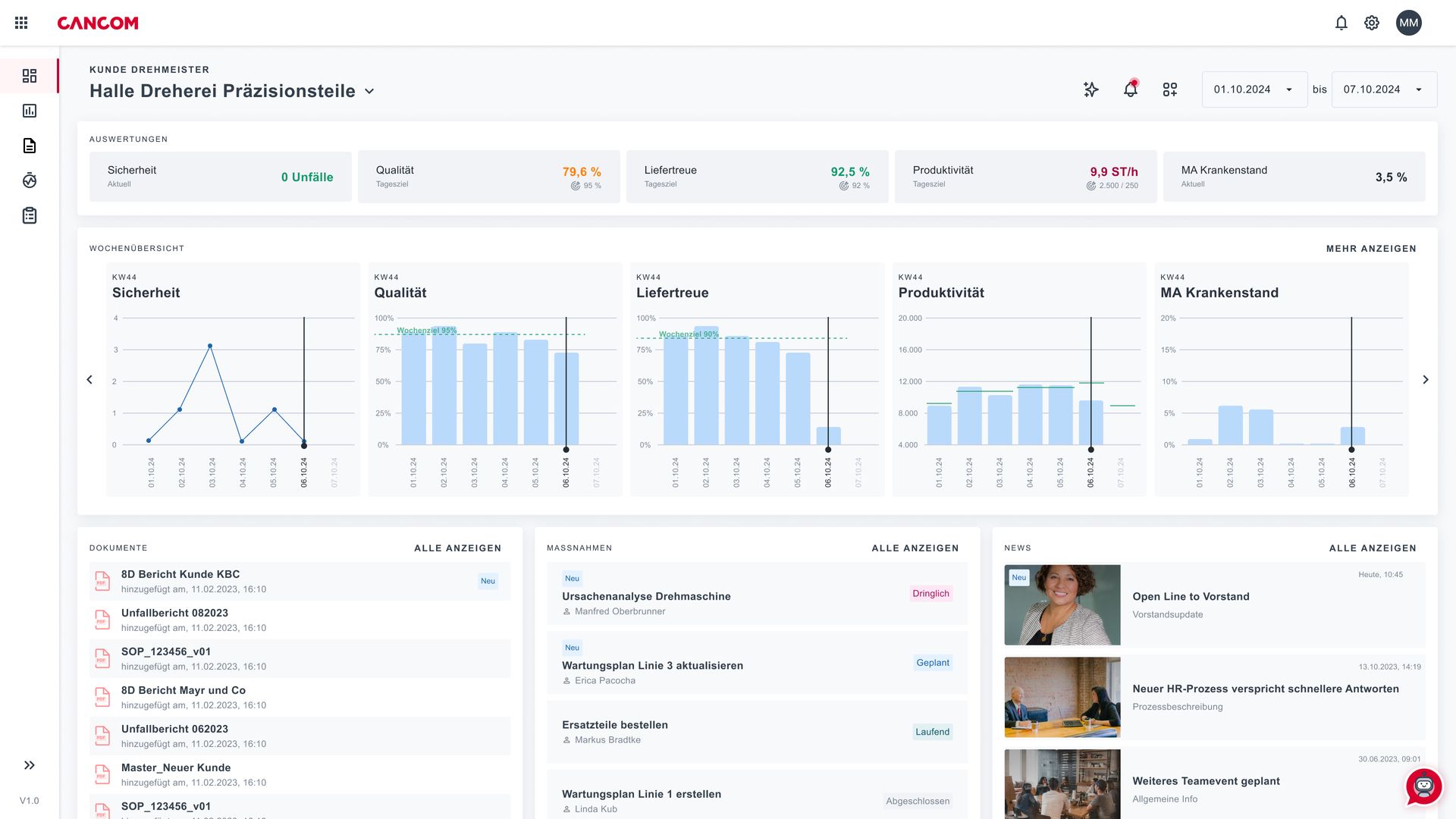

By setting up a central data platform, machine data, measured values and other relevant data points from different sources are brought together. This creates a networked, robust database that enables seamless integration, analysis and use across different systems and plants. The platform thus creates the basis for data-driven optimization, the use of AI, machine learning and Industrial AutoML - central levers for anomaly detection, predictive maintenance and new, data-based business models in Industry 4.0.

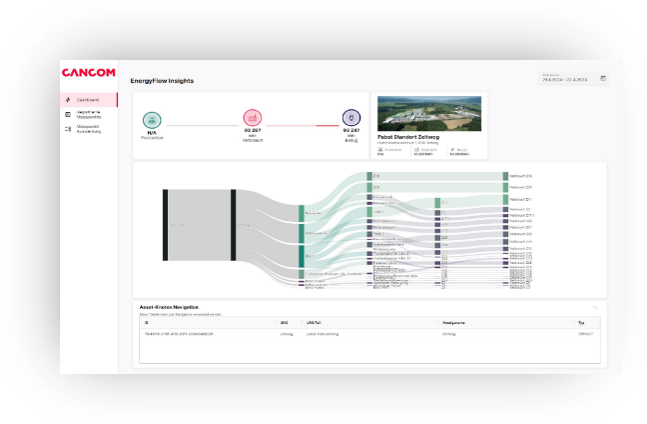

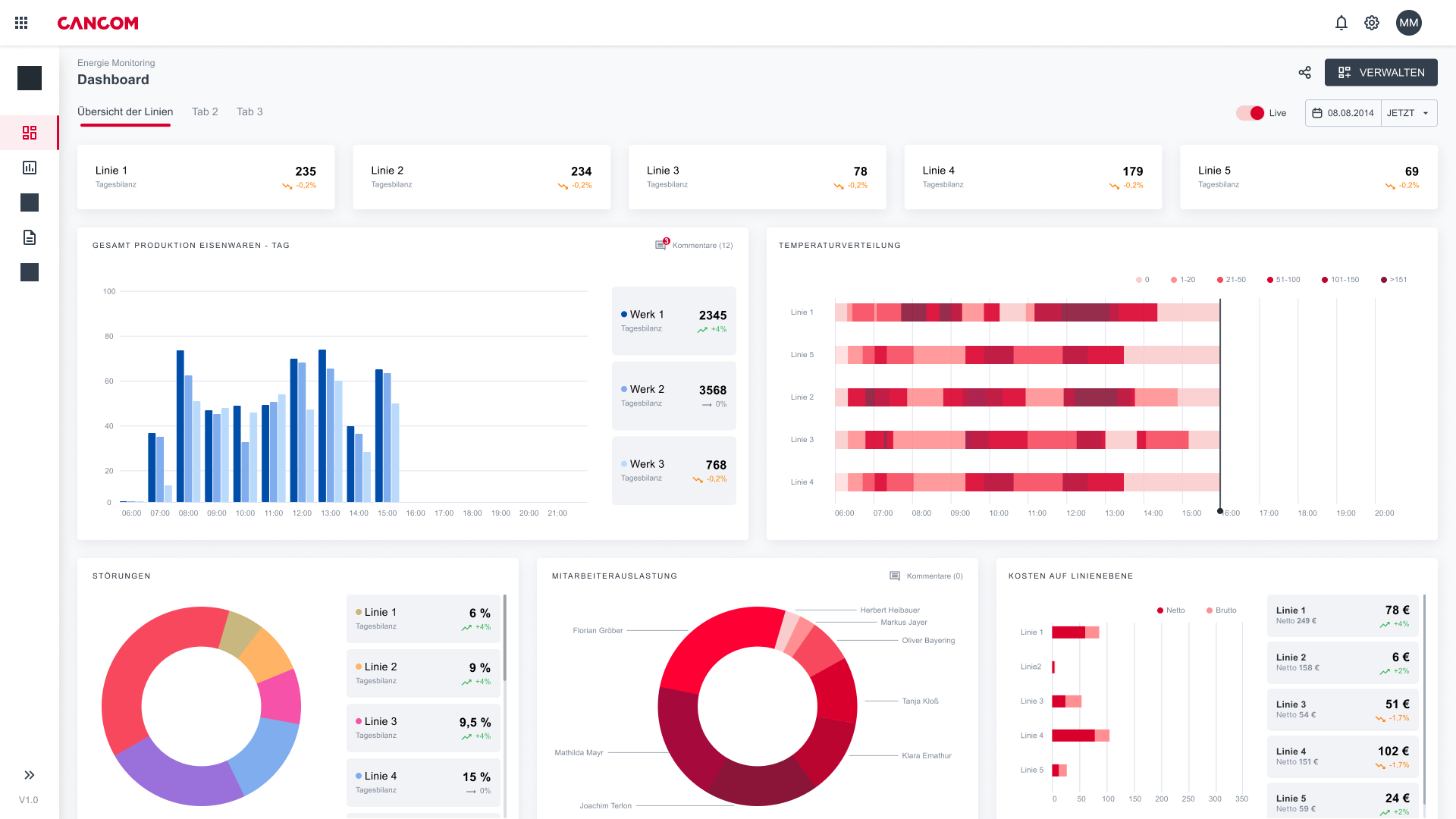

The Industrial Data Platform not only acts as a central factory data hub, but also as a powerful interface for connecting heterogeneous IT and OT systems. It enables companies to create individual reports quickly and efficiently and helps to automate the planning of production processes.

In addition, the platform actively supports the AI transformation in the industry by providing real-time data that enables proactive control, optimization and data-driven adaptation of production processes. It thus makes a significant contribution to the implementation of modern industrial data use cases and the development of new added value through data-driven applications.

.png)